D&L Industries Inc., the parent company of Chemrez Technologies, Inc. and Natura Aeropack Corporation, has embarked on a next-generation expansion plan adding a meaningful capacity in the ECO product space in food, home care, and personal care segments.

The new facility sits on a 26-hectare property in First Industrial Township Special Economic Zone in Batangas. Total capital expenditure is around $300m.

The said facilities will enable a significant move from selling raw materials in bulk to “retail packed at source”. D&L will process a new generation of coconut-based raw materials and package them into consumer-facing products, simplifying supply chains and saving cost.

What sets D&L apart is that it manufactures, innovates in raw materials, formulates, and packs retail-ready – a fully integrated approach.

The new plant will be instrumental to the company’s future growth, with plans to develop more high value-added coconut-based products and penetrate new international markets. It will cater to D&L’s growing export business in the food and oleochemicals segment. It will add the capability to manufacture downstream packaging, capturing a more significant part of the production chain. This will allow D&L to move a step closer to its customers by providing customized solutions and simplifying supply chains, which is highly important given global logistical challenges and concerns.

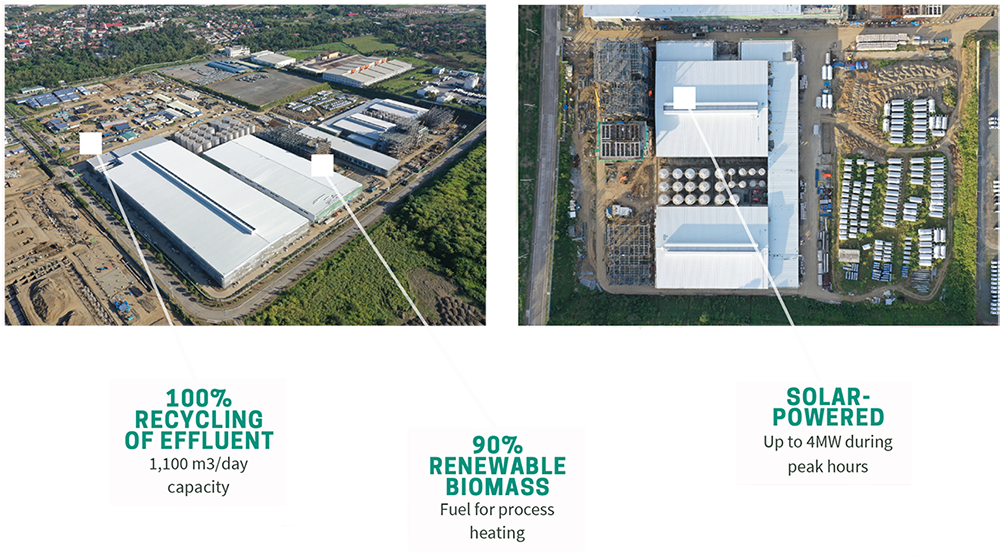

The new facility showcases state of the art technology in manufacturing and global best practices in incorporating sustainability in operations. Below are some of the key sustainability features of the said facility.

- Sustainably designed building and a central command center – Energy and water efficiency, c02 emission reduction, and excellent indoor air quality are incorporated in the overall design of the new facility. In addition, a central command center will house the monitoring of all key environmental elements. It will also house the centralized security, risk management, and business continuity departments of the company.

- Renewable energy sources – A significant portion of the new facility’s power requirement will be coming from solar power gearing the plant towards zero carbon emissions. The facility is designed to harness up to 4MW of solar power during peak hours of 9am to 3pm. In addition, 90% renewable biomass will be used to produce the steam used in process heating.

- Chilled water system – All cooling requirements of the new facility will be centralized. This is expected to translate into greater energy efficiency and lower maintenance costs.

- Water retention system – Surface run-off and rainwater will be collected in a water retention pond which can store up to 5 days’ worth of plant’s water requirements. This is expected to mitigate risk of water scarcity.

- Sensors throughout the facility – Several sensors will be installed throughout the facility to monitor various indicators such as water turbidity and acidity levels, effluent leakage and other possible contamination. With sufficient sensors installed, any abnormal reading will be easily detected and corresponding corrective action can be promptly done.

- Continuous Emission Monitoring System (CEMS) – The company will install its own CEMS to consistently test boiler emissions. This is part of the company’s initiatives to track and reduce its overall emissions.

- Noise monitoring system – In order to monitor and minimize noise pollution, noise monitors and sensors will be installed in the noisiest part of the plant to ensure adherence to the limits set by the park and to also ensure the surrounding communities are not adversely affected.

- Tree planting – The company will do a tree planting activity to surround its new site with hybrid coconut trees subject to approval from the industrial park management.

The international market for plant-based foods (dairy alternatives) and natural and sustainable (palm- and petroleum-free) home and personal care products is growing rapidly. The company now looking for progressive brand owners and retailers to work with to set standards, product ranges, and packaging options.